History of “Print”

Today we are not alien to the “Print Process”. We use a lot of printed materials in various forms in our daily life. The print has become an inevitable part of humankind. From the morning newspaper to milk pouches, from books to packaging materials, from photographs to billboards, printing has become an essential part of our lives.

Since its invention, the process of printing process has seen a drastic evolution in the patterns, technology, methods, approach and all the other aspects involved. In this article, we are sharing some interesting facts and information, to let you know how printing has evolved to its contemporary form.

The World before Print: Before the invention of the printing presses, any writing or documentation, drawings had to be done by hand. Of course, it was a lengthy and tiring process. A lot of resources were required for multiple creations of the materials.

Around the late 1430s, Johann Gutenberg (Germany) was finding a way to make money. There was a trend in attaching small mirrors to one’s hat or clothes to soak up healing powers when visiting holy places or icons. The mirrors themselves were not significant, but Gutenberg quietly noted how lucrative it was to create mass amounts of a cheap product. During the 1300s to 1400s, people had developed a very basic form of printing. It involved letters or images cut on blocks of wood. The block would be dipped in ink and then stamped onto paper.

Gutenberg already had previous experience working at a mint, and he realized that if he could use cut blocks within a machine, he could make the printing process a lot faster. Even better, he would be able to reproduce texts in great numbers.

Instead of using woodblocks, Gutenberg used metal instead. This became known as a “movable type machine,” since the metal block letters could be moved around to create new words and sentences. With this machine, Gutenberg made the very first printed book, which was naturally a reproduction of the Bible. Today the Gutenberg Bible is an incredibly valuable, treasured item for its historical legacy.

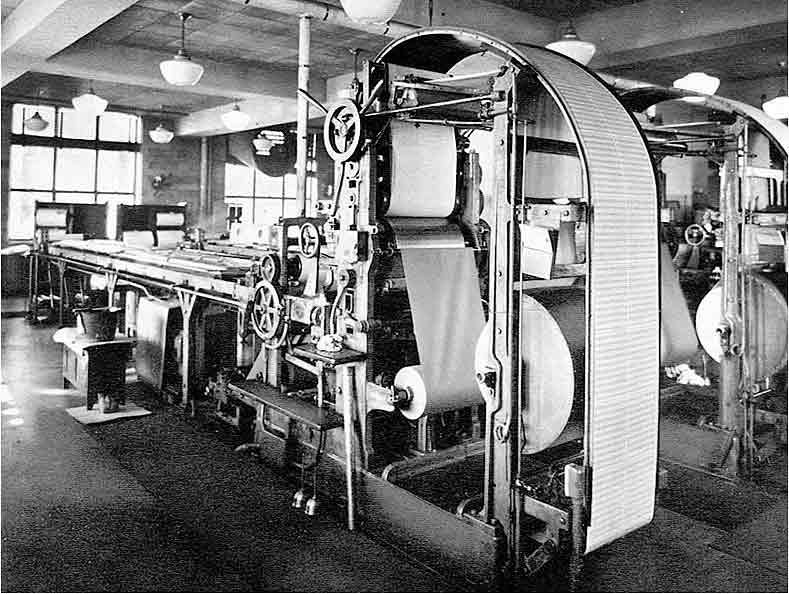

Evolution of Printing: With the original printing press, a frame is used to set groups of type blocks. Together, these blocks make words and sentences; however, they are all in reverse. The blocks are all inked and then a sheet of paper is laid on the blocks. All of this passes through a roller to ensure that the ink is transferred to the paper. Finally, the paper is lifted, and the reader can see the inked letters that now appear normally as a result of the reversed blocks.

These printing presses were operated by hand. Later, towards the 19th century, other inventors created steam-powered printing presses that did not require a hand operator. In comparison, today’s printing presses are electronic and automated, and can print much faster than ever before! Today, there are multiple types of printing presses, each best for a specific type of printing. They include:

Letterpress:

Similar in concept to Gutenberg’s press, letterpresses require an operator to set movable type, ink it, and press paper against it. The entire process is done by hand. The letterpress is often used by small, boutique printers, and offers a beautiful handmade look. However, it’s also inefficient and expensive compared to other printing presses.

Offset press:

The offset press revolutionized the printing industry, making it possible to print enormous quantities efficiently and cost-effectively. In a nutshell, modern offset printing involves using a computer to create a plate, which is then placed on a cylinder. Ink is applied to the plate cylinder, which rolls against a rubber cylinder, which in turn rolls the ink onto sheets of paper fed through the press. Offset presses are used to mass-produce newspapers, magazines, books, and other printed materials.

Digital press:

One of the few drawbacks to offset printing is that it’s not economical in low volumes, primarily because plates can cost several hundred dollars to produce. That’s insignificant when printing hundreds or thousands of the same item, but it can be costly when printing a few dozen or even a single copy. Digital presses make low-volume printing affordable and have similarly revolutionized the printing industry because they do not require plates. Instead, they use advanced inkjet or laserjet technology to transfer ink to paper.

Flexography Printing:

Flexography (often abbreviated to flexo) is a form of printing process which utilizes a flexible relief plate. It is essentially a modern version of letterpress, evolved with high-speed rotary functionality, which can be used for printing on almost any type of substrate, including plastic, metallic films, cellophane, and paper. It is widely used for printing on the non-porous substrates required for various types of food packaging (it is also well suited for printing large areas of solid colour).

Flexo has an advantage over lithography in that it can use a wider range of inks, water-based rather than oil-based inks, and is good at printing on a variety of different materials like plastic, foil, acetate film, brown paper, and other materials used in packaging.

Rotogravure Printing:

Rotogravure (or gravure for short) is a type of intaglio printing process, which involves engraving the image onto an image carrier. In gravure printing, the image is engraved onto a cylinder because, like offset printing and flexography, it uses a rotary printing press.

Gravure is an industrial printing process capable of consistent high-quality printing. Since the Gravure printing process requires the creation of one cylinder for each colour of the final image, it is expensive for short runs and best suited for high volume printing. Typical uses include long-run magazines in excess of 1 million copies, mail order catalogues, consumer packaging, Sunday newspaper ad inserts, wallpaper and laminates for furniture where quality and consistency are desired.

The printing industry in India: The printing industry in India is more than 200 years old. Over the years, and more so during the last 50 years or so, it has grown steadily, keeping pace with the growth of information, education, communication and computers. Today, it serves as one of the major media of communication, perhaps even more so than radio, television, and other forms of communication. The industry comprises well over 58,000 establishments and it is involved in several activities, such as the publication of newspapers, magazines, books, outdoor publicity materials. Etc.

The quality of printing on these machines was better than platen and stop-cylinder presses and this initiated textbook printing in India, at least for senior school level, in a very small way. As the freedom struggle kept pace with the repressive administration of the British Raj, the printing industry marched along in both sectors — private and government. Despite repressive measures of the British Raj, newspaper printing/ publishing became an important tool for the freedom struggle at that time and several English and regional language newspapers appeared on the scene – broadcasting was almost negligible and government-controlled.

The printing industry in India in 1897 was at its infancy, making hand-impression of the composed and engraved areas. The art of makeready of any printed area was not much known as the platen machines were being used in the first decade of 1900. Stop-cylinder machines were introduced by some printing houses in Bombay, Madras, Calcutta, and Delhi. Later in the early 1940s Miehle Presses, known as two-revolution presses, were introduced in India initially by government-run presses and then by commercial printing houses in major cities.

During the period 1925-1946, many small-time printers contributed to the printing of news bulletins, both in Hindi and Urdu and other regional languages. Textbook printing was also undertaken by these printers which came as spillover from big publishing/ printing houses. Most of these books were either side-stitched and cover drawn upon or centre stitched along with softcover. Some hardcover copies were also produced and our master binders perfected this art just by manual binding.

There were only three big names in the publishing field in pre-Independence days – New Longman, MacMillan and Oxford University Press. But in the last 67 years, there has been unbelievable growth in the field of publishing/ printing. One cannot ignore the contribution of NCERT in textbook publishing besides Orient Longman, S Chand, Frank Brothers, names like Vakils & Sons; Bolton Fine Arts; Conway Printers; Bombay Offset; Sri Saraswati Press; Eagle Litho; NK Gossain Press; Prasad Process; Commercial Printing Co; Thomson Press; Mehta Offset — who printed millions of different titles in various languages in association with local, American, and British publishers.

However, a major segment of the printing industry remains small-scale even after 70 years of independence, characterised by low investments and somewhat outdated technology. By the early 1980s, 90% of the printing presses installed in the small-scale sector were letterpress units with semi-automatic composing or hand-composing facilities. Only 5 to 6% presses in 1975-80 had full mechanical composing, either mono, lino, or photo-composing with offset process printing facilities as compared to the technological innovations taking place during those years in other parts of the globe.

There has been rapid modernisation in the printing industry in the last two and half decades. And it is for certain that in the next 10 year’s time, installation of the latest and upgraded computerised equipment in pre-press and post-press areas will create a concentrated environment in retaining most of the state-of-the-art printing jobs from going overseas countries like Hong Kong and Singapore.

Indian print industry experts and print associations are of the view that time is not far off when India will become a printing hub of entire Asia. Presently, the Indian Print Industry is twice the size of the Indian Film Industry and is marching towards a turnover of USD 30 billion with double-digit growth.

The Covid Pandemic has severely impacted various industries across the globe including the printing industry. This industry has huge potential and a promising future with the innovations, research and development already in process.

At “PRINT IMAGE” we ensure that we carry a legacy of this rich and legendary industry. Our team of expert & qualified professionals with 10+ years of experience in the Offset & Digital printing industry can undertake all kinds of printing services. We are specialists in customized printing various types of printed materials like POS (Point of Sale) materials, brochures, calendars, diaries, cartons, Fabrication jobs, Displays & more…

As your Printing Partner, we are capable of transforming ideas & concepts into reality. We are always ready to take responsibility & accountability for your printing jobs, so you can sit back and relax. Print Image is your consultant and marketing service provider, engaged in TTL– through the Line activity (ATL + BTL). We understand that printing is an eleventh-hour activity and the print collaterals represent your company’s reputation in your day-to-day business. We strive to deliver in time with high-quality products at competitive rates.

With our commitment to exceptional quality and services delivered to the industry, we look forward to building a relationship that lasts longer and stays stronger!

For more details, please contact us at: +91 9819 882 441 / +91 22 4979 4546 or send a mail at: vijay@printimage.co.in or visit our website: https://print-image.in/

© 2025 PRINT IMAGE. Built using WordPress and OnePage Express Theme.